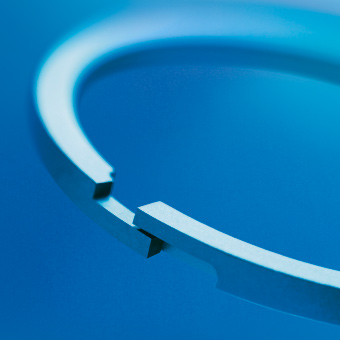

PTFE Piston Rings

PTFE Guide Rings (Rider Rings)

PTFE Piston Rings and Guide Rings (Rider rings) for dry-running applications are currently a focal point of technical development.

They significantly reduce a machine’s operating costs and, in today’s increasingly environmentally aware society, make it easier for operators to fulfill stricter environmental legislation.

ElringKlinger Engineered Plastics offers a whole range of PTFE piston sealing rings (Guide rings or rider rings for reciprocating compressors).

These products are made possible thanks to our comprehensive technological know-how and our many years of experience with countless customer projects.

We are able to create specially developed PTFE compounds, e.g., for dry-running seals and guides, such as those used in reciprocating compressors—with the help of innovative production processes. Thanks to their specifically adapted filler proportions, these compounds offer decisive advantages:

Essential Advantages:

- Exceptionally low friction coefficient in combination with metals and plastics

- Antiadhesive behavior without any stick-slip effect

- High elongation properties enabling easy fitting

of sealing and guide rings to one-piece pistons - Exceptionally large temperature range from –200°C to +260°C

- Chemically resistant to almost all solid, liquid, and gaseous media

- Ageing-resistant

- Nonflammable

- Physiologically neutral in the stated temperature range

Application Examples:

- Compressors operating under full- and low-lube conditions

- Gas rotary pumps

- Expansion machinery

- Liquid gas and vacuum pumps

- Rocking piston pumps

- Rotary compressors for loading/unloading of silos

- Generation of oil-free compressed air for the

food processing industry, pharmaceutical industry, and dentistry - Compressed air for the craft and do-it-yourself market

- Pneumatic hammer drills

- Automotive technology, including ride leveling

and air-conditioning systems

PTFE Piston Ring Types

![[Translate to Koreanisch:] Straight Joint [Translate to Koreanisch:] Straight Joint](https://www.elringklinger-engineered-plastics.kr/fileadmin/user_upload/ekkt/produkte/kolben-und-fuehrungsringe/kolbenring_gerader_stoss.jpg)

Straight Joint

Piston rings with straight joints are used for sealing pressure differences above 15 bar.

With this gap, the leakage is slightly higher than with piston rings that have a scarf joint. Because of the high compressor speeds (rpm) typically achieved today, the loss of gas from leakage has only a minor impact on compressor performance.

The amount of gas leakage is negligible.

![[Translate to Koreanisch:] Scarf Joint [Translate to Koreanisch:] Scarf Joint](https://www.elringklinger-engineered-plastics.kr/fileadmin/user_upload/ekkt/produkte/kolben-und-fuehrungsringe/kolbenring_schraeger_stoss.jpg)

Scarf Joint

Piston rings with scarf joints are used for sealing pressure differences above 15 bar. During the run-in period, the sealing effect of scarf joints is slightly better than that of piston rings with a straight joint.

![[Translate to Koreanisch:] Overlapped Joint [Translate to Koreanisch:] Overlapped Joint](https://www.elringklinger-engineered-plastics.kr/fileadmin/user_upload/ekkt/produkte/kolben-und-fuehrungsringe/kolbenring_ueberlappter_stoss.jpg)

Overlapped Joint

The overlapped joint achieves a favorable sealing effect.

For this reason, it is primarily used for sealing gases with a specific light weight. Because of bending stress and the resulting risk of breakage in the overlapping areas, piston sealing rings with overlapped joints should only be used in compressors operating with pressure differences of max. 15 bar.

![[Translate to Koreanisch:] Gas-tight Joint [Translate to Koreanisch:] Gas-tight Joint](https://www.elringklinger-engineered-plastics.kr/fileadmin/user_upload/ekkt/produkte/kolben-und-fuehrungsringe/kolbenring_gasdichter_stoss.jpg)

Gas-tight Joint

Our gas-tight piston rings achieve the best sealing effect.

The special design of the joint reduces leakage to a minimum. The differential pressure is limited to a maximum of 15 bar. During assembly, please note that the piston ring achieves a good sealing effect in one direction of pressure only.

PTFE Guide Ring Types

Guide Ring Versions

![[Translate to Koreanisch:] Guide Ring Version Straight Joint [Translate to Koreanisch:] Guide Ring Version Straight Joint](https://www.elringklinger-engineered-plastics.kr/fileadmin/user_upload/ekkt/produkte/kolben-und-fuehrungsringe/fuehrungsring_gerader_stoss.jpg)

Straight Joint

![[Translate to Koreanisch:] Guide Ring Version Scarf Joint [Translate to Koreanisch:] Guide Ring Version Scarf Joint](https://www.elringklinger-engineered-plastics.kr/fileadmin/user_upload/ekkt/produkte/kolben-und-fuehrungsringe/fuehrungsring_schraeger_stoss.jpg)

Scarf Joint

![[Translate to Koreanisch:] Guide Ring Version Continuous [Translate to Koreanisch:] Guide Ring Version Continuous](https://www.elringklinger-engineered-plastics.kr/fileadmin/user_upload/ekkt/produkte/kolben-und-fuehrungsringe/fuehrungsring_endlos.jpg)

Continuous

![[Translate to Koreanisch:] Guide Ring Version Shouldered with Straight Joint [Translate to Koreanisch:] Guide Ring Version Shouldered with Straight Joint](https://www.elringklinger-engineered-plastics.kr/fileadmin/user_upload/ekkt/produkte/kolben-und-fuehrungsringe/fuehrungsring_geschultert.jpg)

Shouldered with Straight Joint

Laminated Piston

PTFE Laminated Piston

Benefits of the PTFE Coated Piston Compared with Standard Guide Bands and Rider rings

- The specific surface pressure is reduced by coating the entire piston skirt all the way to the seal groove. By maintaining a low radial section of the bearing element, thermal expansion is reduced allowing significantly lower running clearances to be specified.

- Reduced running clearance largely prevents piston slap, resulting in significantly smoother operation

- Improved heat transfer from the piston to the cylinder wall due to the low coating thickness and large contact surface area

Tipseal - square gasket for scroll compressors

Application

- oilfree scroll compressors

- stationary and mobile use (e.g. refrigerant)

Advantages

- long durability

- low wear

- high temperature range: -200°C up to +200°C

- low energy consumption

- less vibrations

- customized design (cut design) and material choice