Laminates

Laminates Based on PTFE and Modified PTFE

Laminates are reinforced PTFE, consisting of a PTFE film or plate on the one hand and a substrate on the other. The layers of material are firmly bonded to each other.

Possible substrates include fabrics, fibers, or knitted fabrics as well as films. They consist, for example, of glass, metal, ceramics, elastomers, or high-performance polymers.

The structure may comprise two or more layers, and constructions with up to 7 layers are not uncommon.

Essential Advantages:

- Outstanding resistance to a wide range of chemicals

- Very broad functional temperature range, only limited at the upper end by resistance of the adhesive used

- Very good antiadhesive properties

- Dimensional stability and resistance to stress cracking

- No embrittlement, no ageing

When modified PTFE is used as a film material, these properties are enhanced further by:

- Polymer structure with higher density and fewer pores

- Lower permeability

- Better weldability

Application Areas

- Linings in plant engineering

- Components for electrical and electronic applications

- Diaphragms in pump or sensor construction

- Optically transparent compounds for textile construction

Xymon

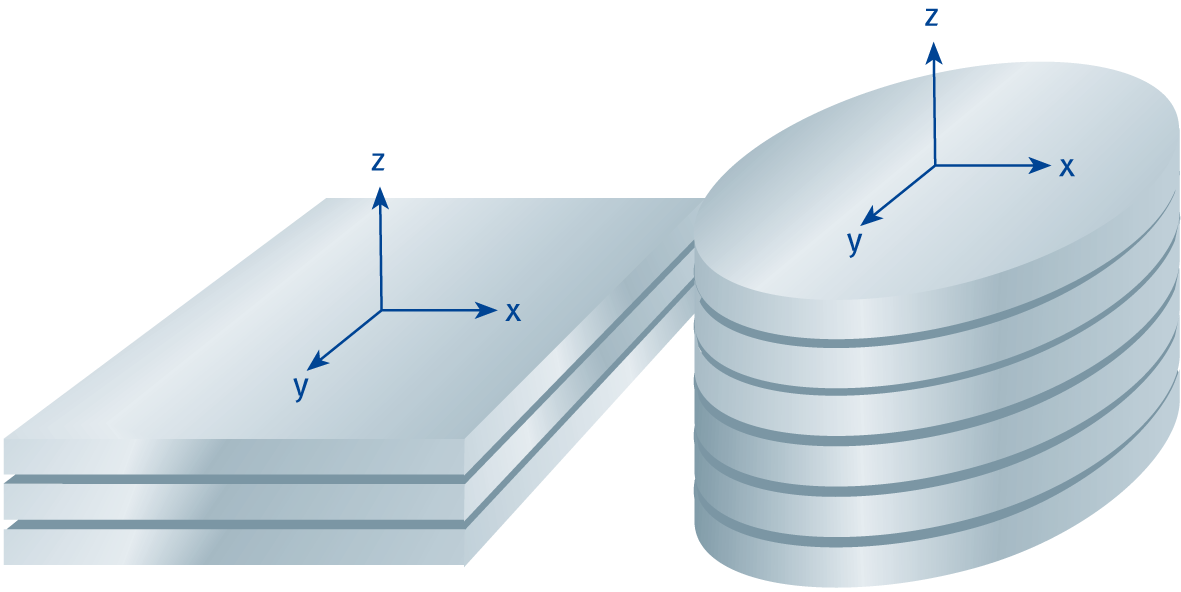

Xymon is a fluoropolymer compound reinforced by long carbon fibers (C fibers) with an anisotropic property profile. It is manufactured as a plate, disc, or ring. The main orientation of the long carbon fibers is as follows in the xy plane:

Properties

- Almost universal chemical resistance

- Extremely high tensile strength

- High pressure resistance

- Superior cold flow resistance

- High abrasion resistance

Application Areas

- Valve seals

- Bearings

- Fittings

- Valve seats

- Flat gaskets

- Pump vanes

- Valve components

- Piston rings

- Automobile seals

Compared with unfilled PTFE or typical compounds with carbon fiber or fiberglass filler, there is an enormous gain in properties, measured parallel to the fiber orientation:

| XYMON UC-3000 | XYMON UC-1500 | |

|---|---|---|

| Modulus of elasticity | 10,000 MPa* | 5,000 MPa* |

| Tensile strength | 60 MPa* | 45 MPa* |

| Deformation under load | < 1% | < 2% |

*Parallel to fiber orientation

Chemical Resistance

The very good resistance of the C fibers and the fact that they are tightly enclosed by the fluoropolymer give Xymon its unique resistance, which closely approaches that of pure PTFE. The material may be used, for example, in hydrofluoric acid, hydrochloric acid, phosphoric acid, mineral oils, tetrahydrofuran, and many other media.